With the constant breaking of T2 axles, I decided it was time to upgrade the differential to none other than the Ford 8.8. I began to collect parts for the conversion, which I became very thankful for after breaking my T2 diff at Drift Week 2. I got a whopping three laps before my diff seized, turns out it had no oil in it, another costly mistake.

The 8.8 is an obvious choice for many reasons; readily available, tons of aftermarket parts, and they already make a conversion kit. I ordered the conversion kit from Ronin Speedworks and got the “grande kit” which includes new hubs. The new hubs make it so I can use the 8.8 outer CV joint. Eliminating all T2 CV components. A friend had ordered the same conversion kit and I helped him install it, so I already knew my way around doing this install.

For the 8.8, I decided on a few options:

Motive Performance 4.56 gears

Motive Performance master gear install kit

Solid pinion spacer

Ford Trac lok

Ford Racing LSD rebuild

G2 diff cover

1989 Ford pinon flange (1310 U-joint)

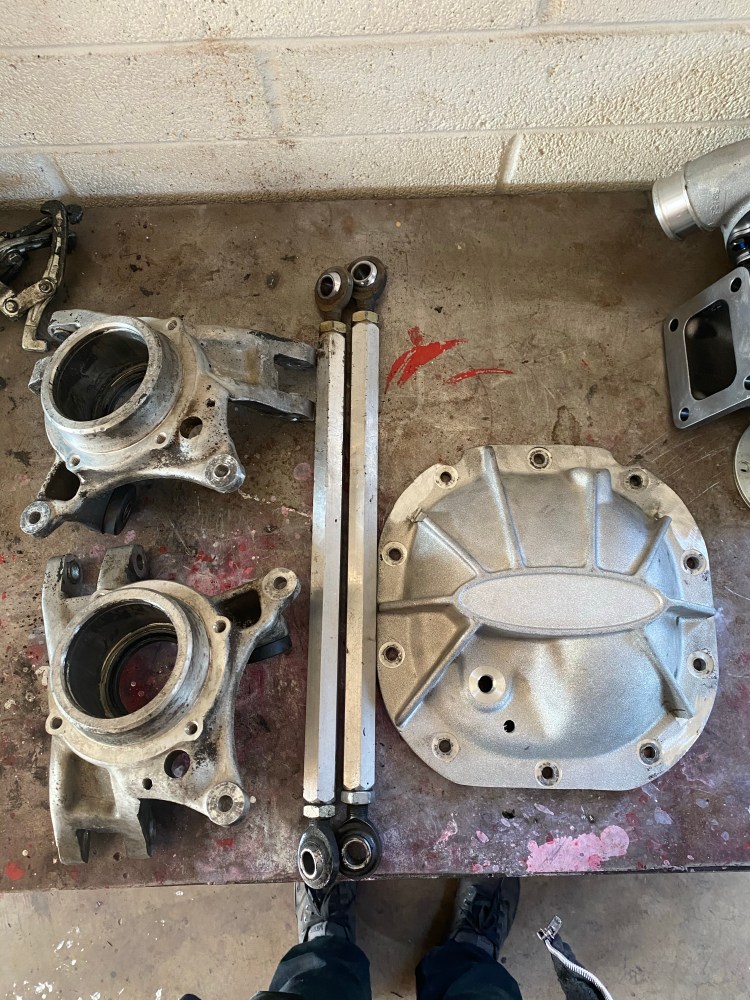

First up was disassembling the diff to remove the tone ring to even have a chance of making this work. I had to grind the inside sides of the cover to clear the bearing caps and bolts. Then I was on to drilling and tapping it for a vent tube since the vent tube was built into the OEM cover. Finally onto trimming the fins to clear the cradle and cutting off some of top of the diff.

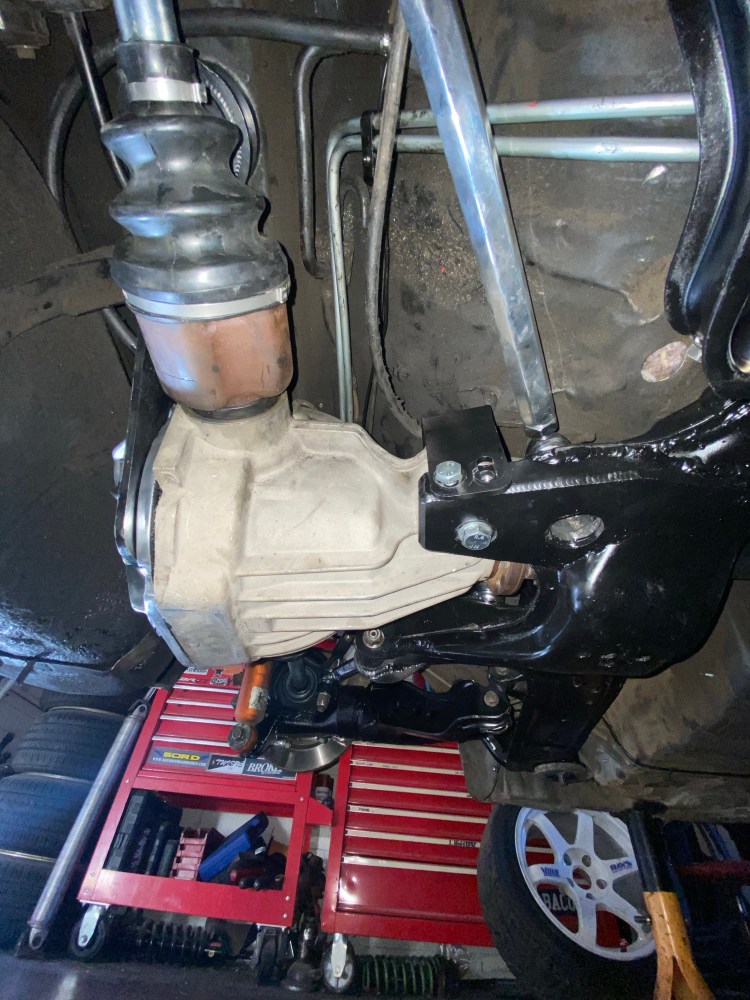

I went on to prepping the subframe, but after all the years of driving and breaking CV’s, it was in dire need of a deep cleaning. I was able to degrease and clean up the subframe at the house, but the trailing arms and knuckles needed much more cleaning, so off to the hood car wash. I test fit the diff and got the brackets tacked in place so I could finish up the welding on the bench.

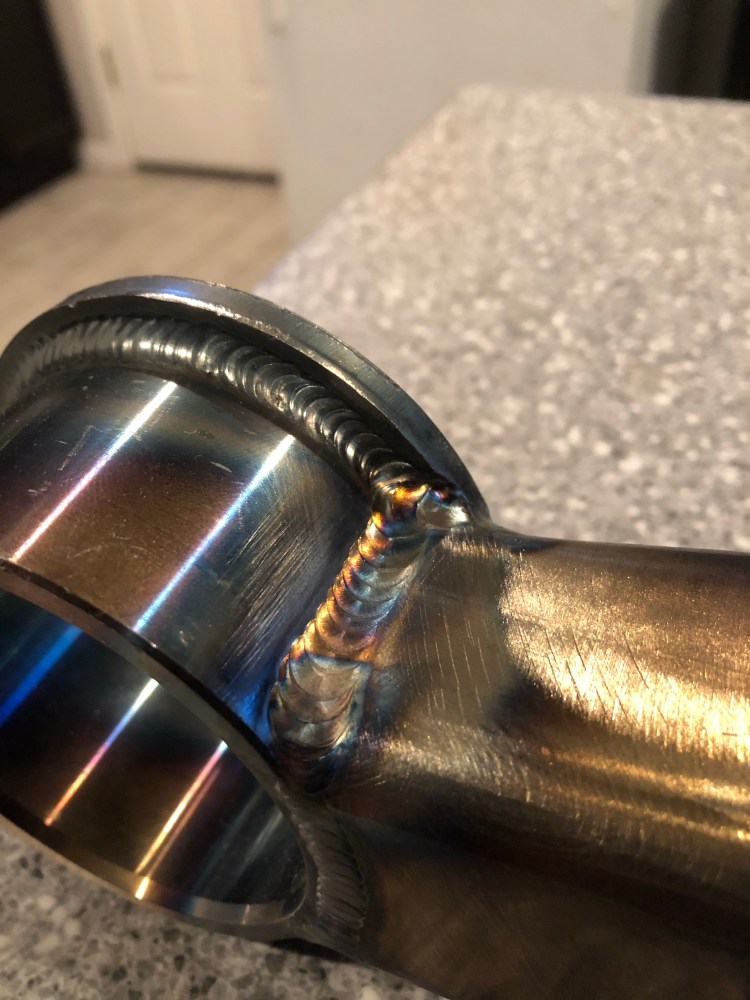

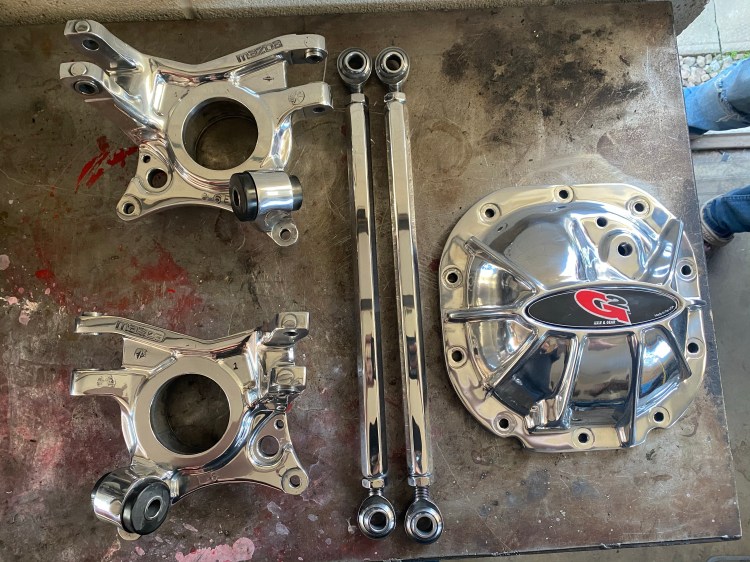

I made up some delrin bushings for the front of the differential and the camber arm. I sent the differential cover, knuckles and toe arms off to get polished, because why not? I disassembled the explorer CV’s, cleaned everything up and assembled it all with the new shafts.

I received the differential back from AZ Differential Specialists and it looks nice. They had some issues fitting the cover since the new 4.56 gear set was thicker and hit the cover. Some more grinder work and I got the cover to fit and everything spin freely. Then it was onto getting everything into the car. I assembled everything as I went versus installing everything and trying to lift the differential and completed subframe into the car. I installed the dual caliper for mockup, but removed it afterwards. It will get installed at a later date, I have a special project in mind for the dual caliper.

Enjoy how everything looks for now, it’ll never look this nice again! ha!